At AMEC, we test EV batteries a lot to make sure they work well, are safe, and last a long time, both in pretend situations and in the real world. This helps us make sure they're really good quality.

Our comprehensive testing includes performance evaluations, safety assessments, and durability testing protocols.

300

AH

Battery Capacity

Development

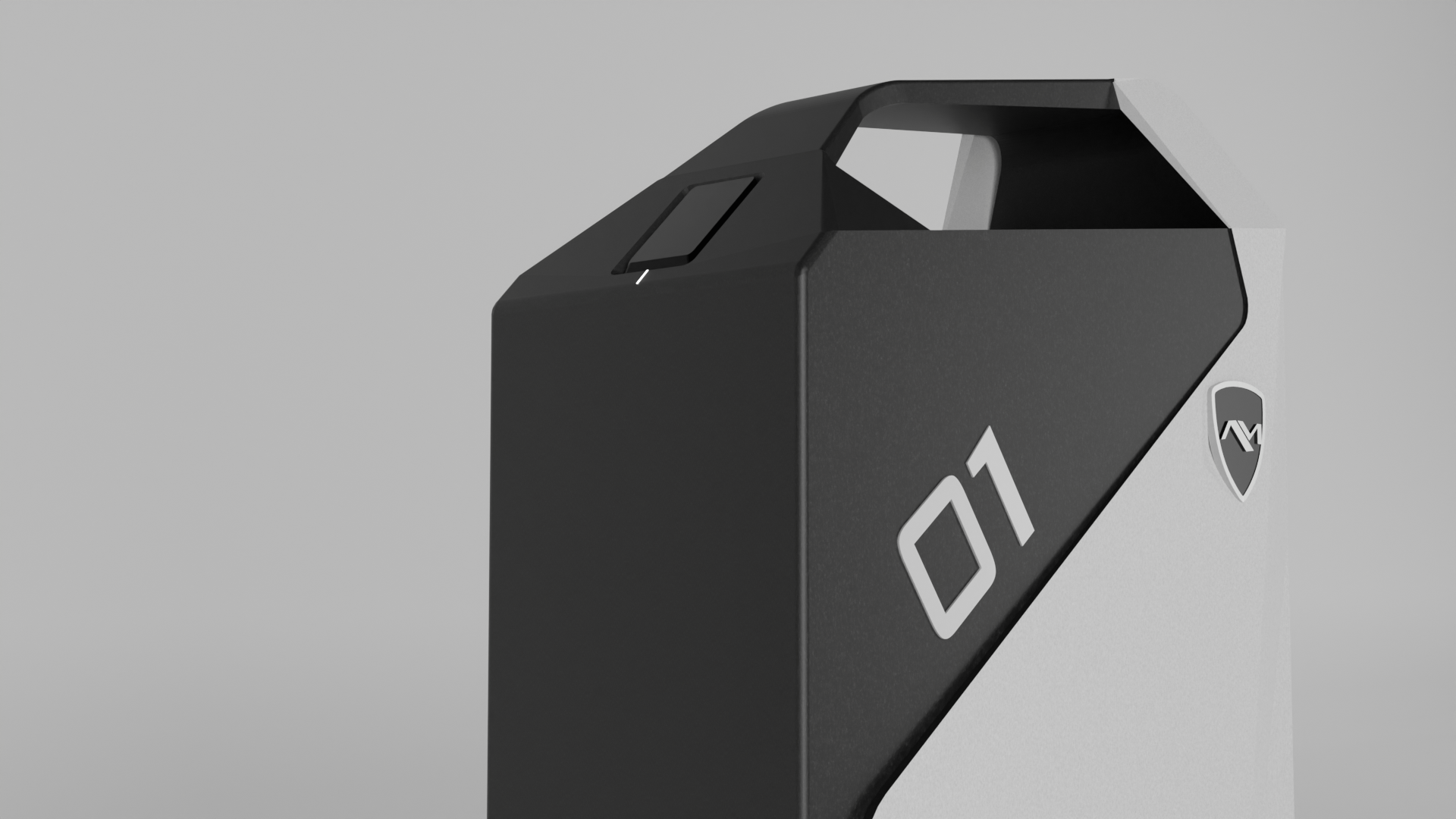

Conceptualization and Design:

- Our experienced team transforms ideas into reality by conceptualizing and designing innovative EV battery packs tailored to meet specific performance requirements and industry standards.

Advanced Manufacturing Techniques:

- We use really advanced ways to make our battery packs with accuracy, making sure they work well and can be made a lot quickly. This helps us make a bunch of them fast and get them to you quickly.

Testing and Validation

Performance Testing:

- Our battery packs undergo comprehensive performance testing to evaluate factors such as power delivery, voltage stability, and energy efficiency, ensuring they meet or exceed performance expectations.

Safety Assessments:

- We do really careful safety tests, like pretending extreme situations and what happens if something goes wrong, to make sure our battery packs are really strong, so there's less chance of anything bad happening, and we follow really strict safety rules.

Durability and Reliability Testing:

- Our battery packs endure extensive durability and reliability testing, simulating real-world usage conditions such as temperature variations, vibrations, and mechanical stresses. This ensures that our batteries withstand demanding environments and deliver consistent performance over the long term.

Calculations:

- We carefully calculate the best energy capacity for our EV battery packs by considering things like how heavy the vehicle is, how far you want to go, and how well it works overall, so you get the best performance and range.

- We also figure out how much power and voltage the battery needs to work right for different electric vehicles, making sure they perform well and fit together.

- We pick the battery cells really carefully, looking at things like how much energy they can hold, how much power they can give, how much voltage they have, and if they're a good value for money. Then, we put them together into our special battery packs we designed, making sure they all work well together and perform great.

- Safety is really important to us. We test our battery packs a lot to make sure they're safe, even in really tough situations, and meet the highest safety standards.

- Our Battery Management System (BMS) is really smart. It keeps an eye on things like how much voltage the cells have, how hot they are, and how much charge they have left. This helps the battery work well, keeps all the cells balanced, and makes sure they don't get too full or too empty

- We're always trying to make things better. We listen to feedback from people using our batteries, keep researching, and keep making them better so they work even better, last longer, and use energy more efficiently.

Improving the manufacturing process and quality control measures can result in a more consistent and reliable battery pack, but the improvement in performance is difficult to quantify.